The machine applies a few pounds of pressure to the ring, which holds the board flat (if it bows up at all). The depth limiting for PCB work is done with a depth limiter relative to a ring that contacts the board. The machine was a little over $6k - introductory price. I'd ask for a milled sample from accuratecnc and measure it under a microscope to check the trace widths. I'm not sure if DeskCNC has cutter compensation. That would also not help with small holes.

#Deskcnc controller board software

I suppose run-out can be compensated for in software just like cutter comp (tool wear) but I have not tried it. It uses 1/4" tooling so I had to buy a collet to get it down to 1/8". I have a Ryobi (Home Depot) router and it is not good for PCB work. I noticed on the accuratecnc specs that spindle runout is not listed. I believe nothing else is available that imports gerbers. It's still a good piece of software and the only choice I have found if yoiu want to roll your own system. It's still readable but who knows for how long: I would suggest downloading the demo here and playing around with it:Īnother thing that irks me is that they closed the DeskCNC forum.

#Deskcnc controller board plus

On the plus side it uses G-code unlike some proprietary language like the others. The author is very adament that rub-out is not needed, despite many requests from DeckCNC users, and T-tech and LPKF both have it. The biggest beef with I have with deskcnc is that there is no rub-out function, just trace isolation.

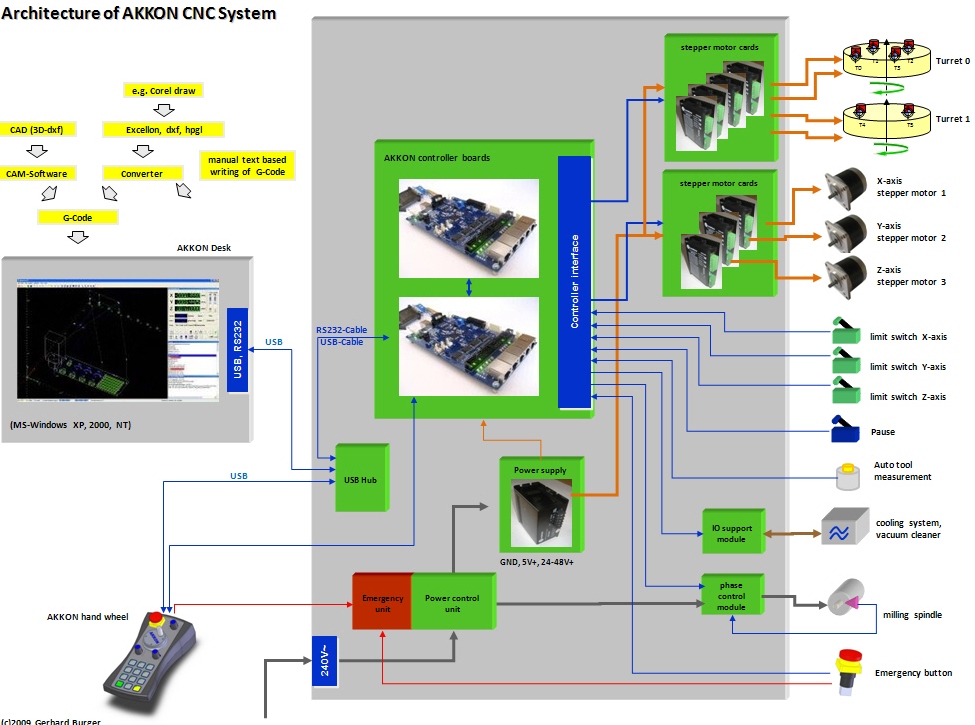

It looks like the accuratecnc product is using DeskCNC ( **broken link removed** )This is the same software/harwdare combo that I used to re-build my router at home (I believe I sent you those pictures a while back). What I can say is that 80% of (these machines) ease of use is in the software. It's still in the box so it may be a while until I try it.

We just bought a LPKF to replace our T-tech.

0 kommentar(er)

0 kommentar(er)